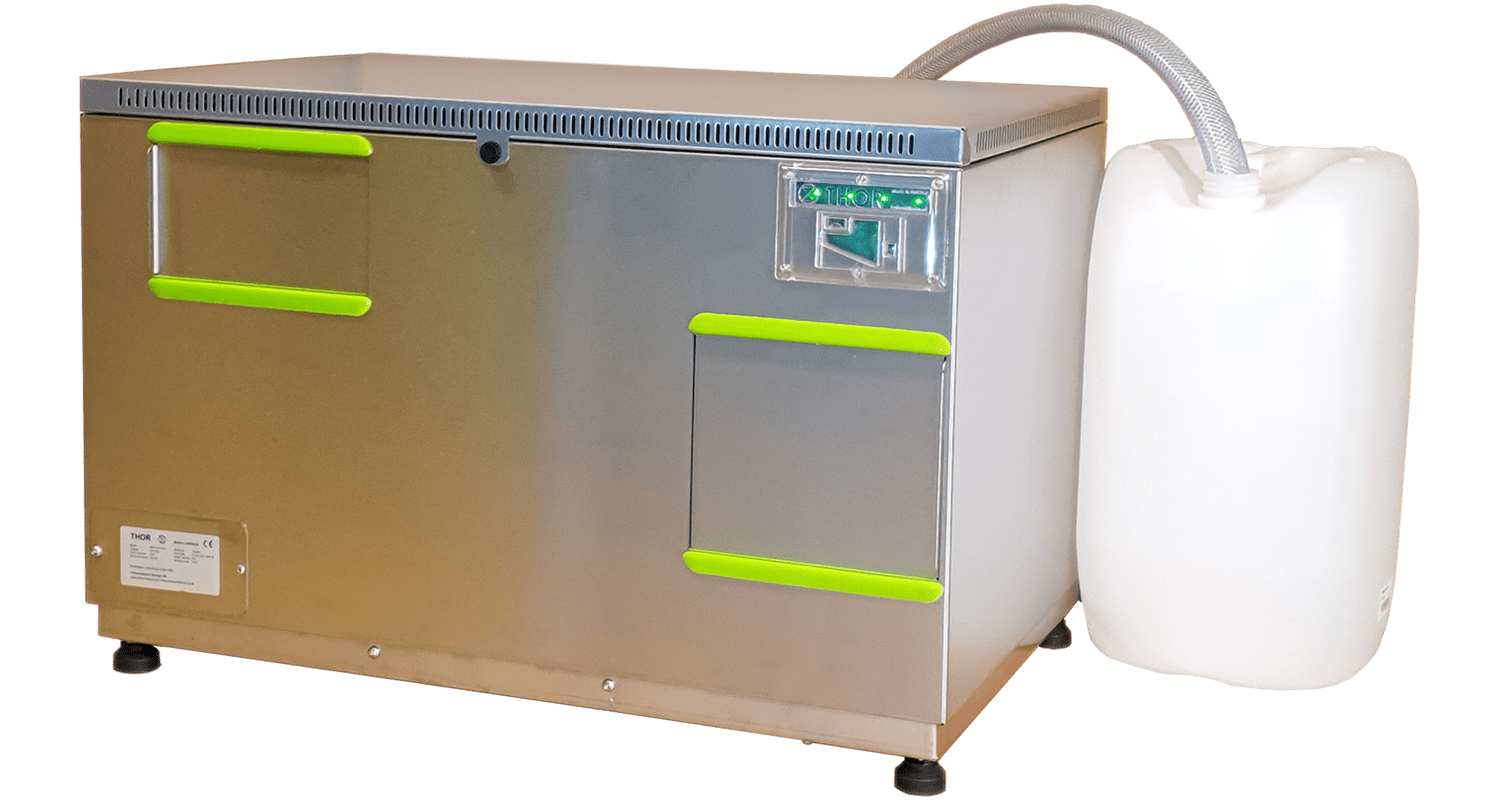

Grease Trap THOR

Made in Sweden

KGs of Co2 emissions that THOR has prevented

An environmental-friendly product that has prevents approximately 5 tons Co² per year per machine compared to passive grease traps.

Fully customizable to suit your needs.

THOR

The grease trap THOR takes the market by storm.

RSK nr: 5643841

Environmental-friendly products for reasonable prices, for all kitchens and companies in need of a grease trap.

The Product Developer

Joakim Fiedler, The Mind behind THOR, has 25 years of environmental-friendly product development, and all features are Therefor optimized and specifically designed

Cleanliness & Effluents

The grease trap THOR is the only grease trap on the market that is self-cleaning and therefore prevents odors and manual cleaning. This prevents methane gas and sulfuric acid for

Environment & Recycling

All plastic and containers that the parts of THOR are shipped in before reasembaling gets either reused or recycled to help the eveorment and to reduce costs

THOR, det gröna och hållbara alternativet!

Products

Made in Sweden

All cartons, plastic, and containers that come with the individual pieces for THOR before the assembly gets recycled or reused in order to preserve the environment.

THOR is quick and easy to install, follow the instructions that come with the grease trap and everything will go as smooth as newly separated grease.

Units and parts are shipped in conjunction with orders in order to preserve the environment and not to create rest products.

THOR

One of Swedens most enviormental-friendly and effective grease traps that also fits in every kitchen

Disinfection system for THOR

A disinfection system for THOR that provides an even cleaner and frecher experience

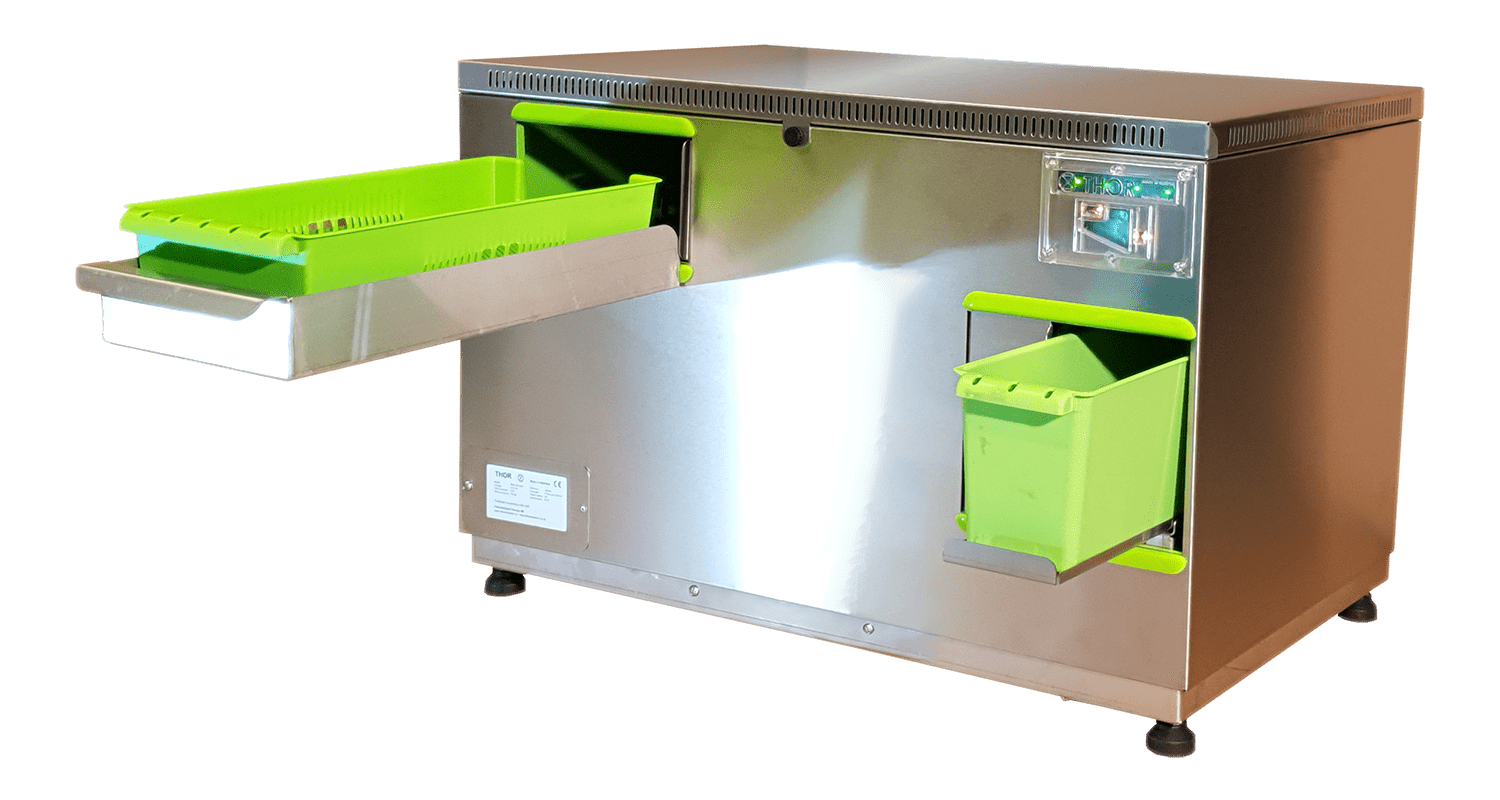

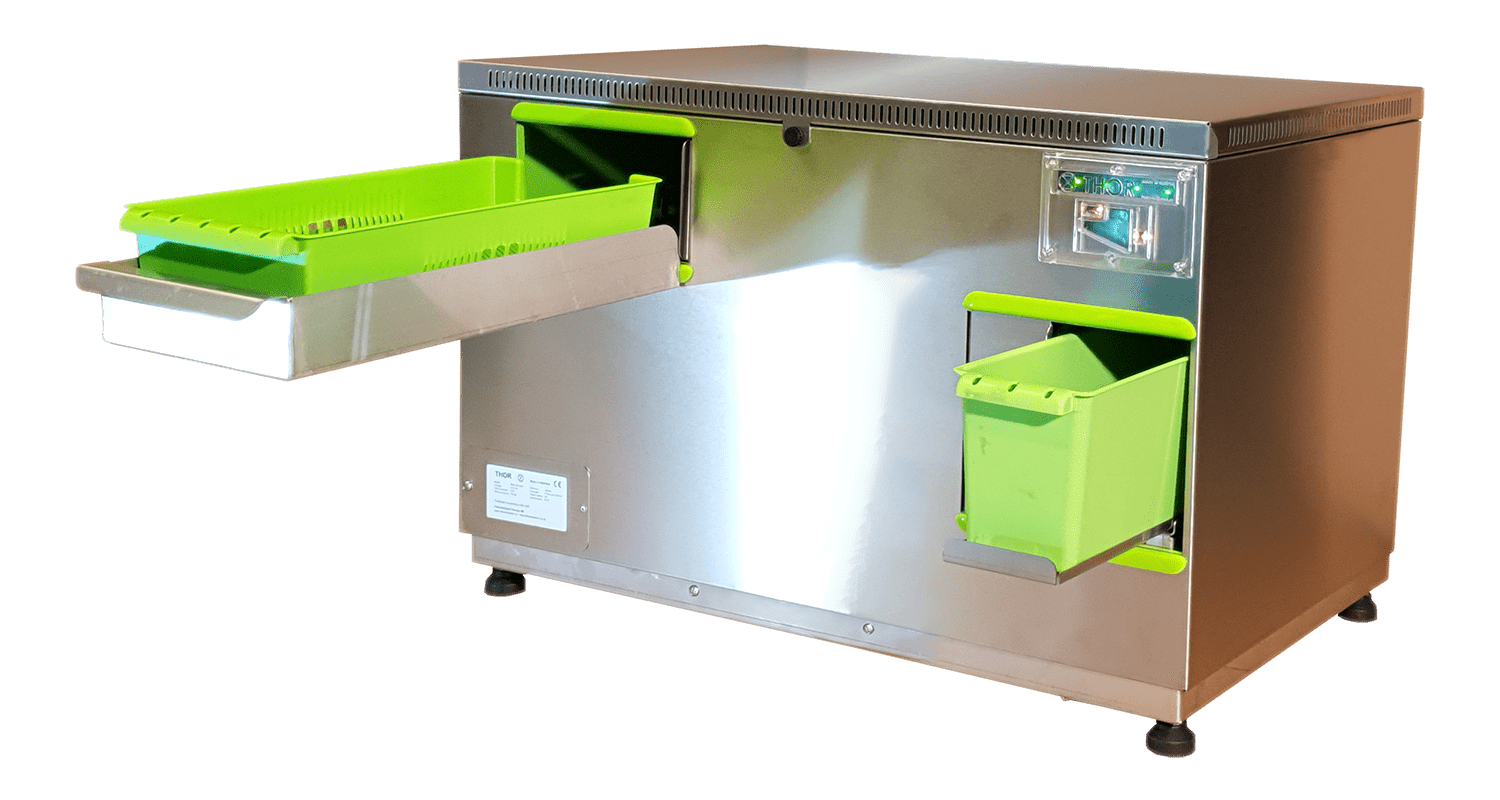

Filter holder for THOR

Filter holder for THOR for a easier extraction of the food filter

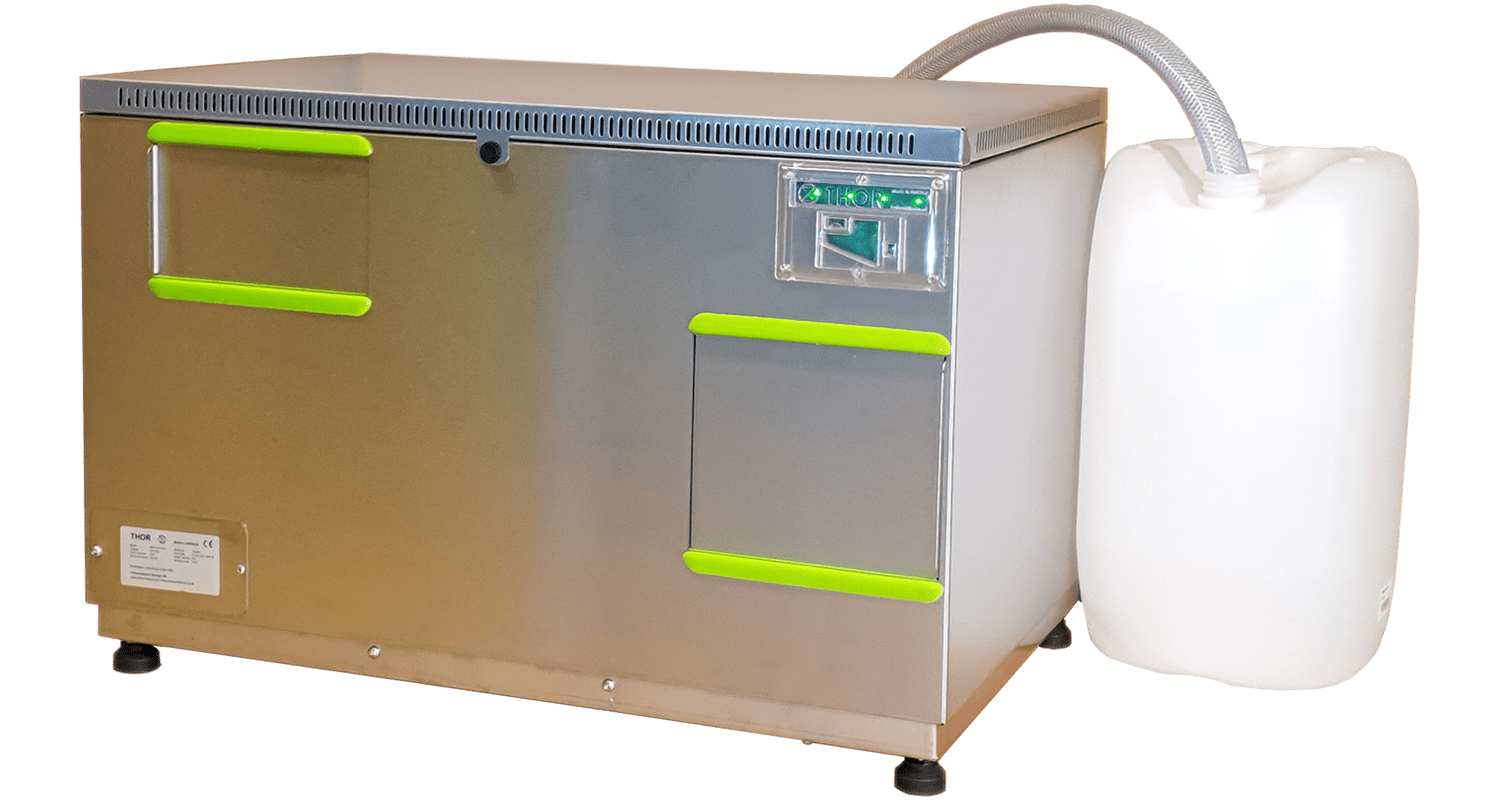

Automatic drainage

Automatic dranage for your THOR to make THOR fitt your specific grease management

The Video shows THOR’s clean design, easy usage and cleaning prosses

THOR

Made in Sweden

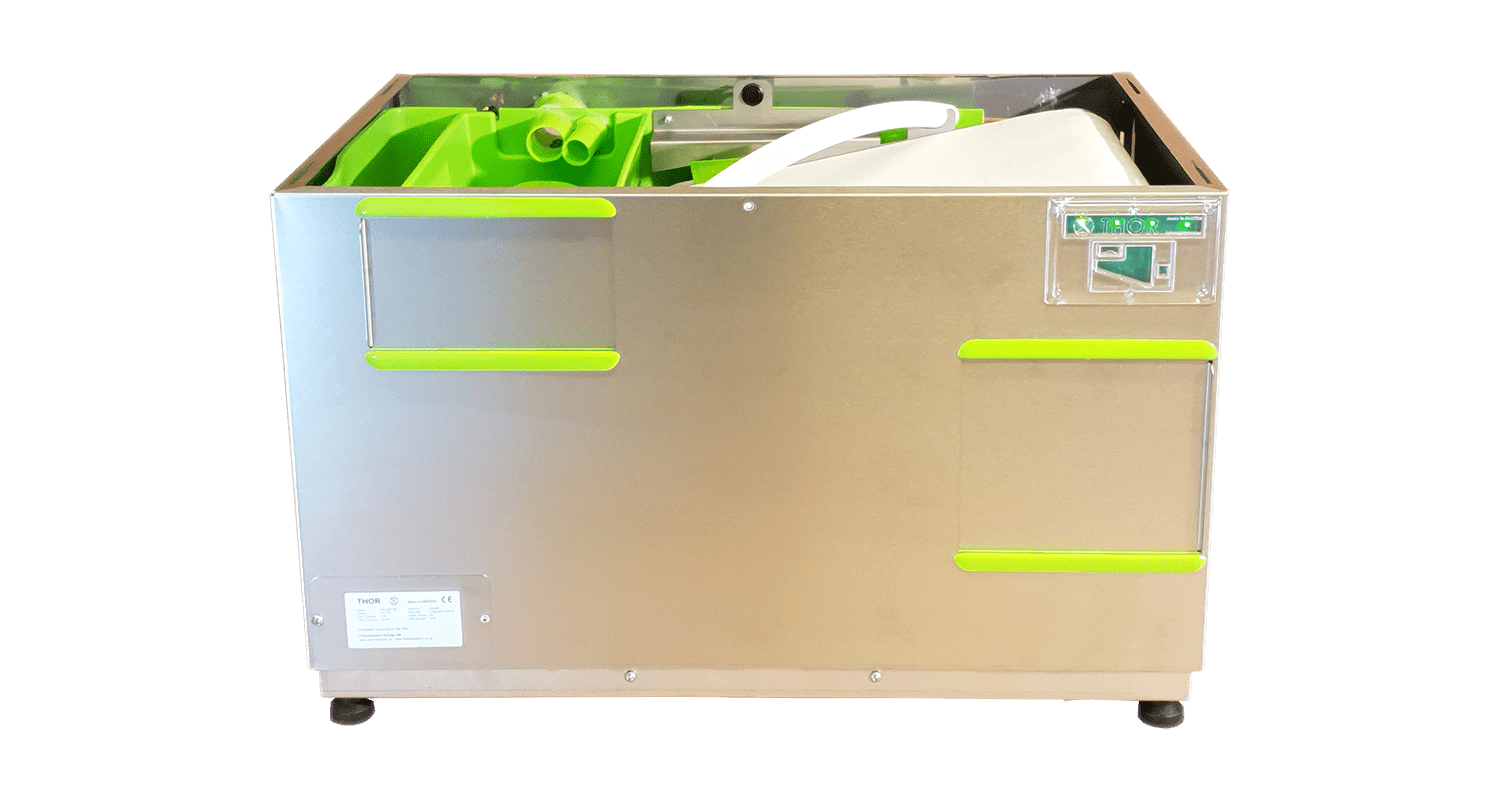

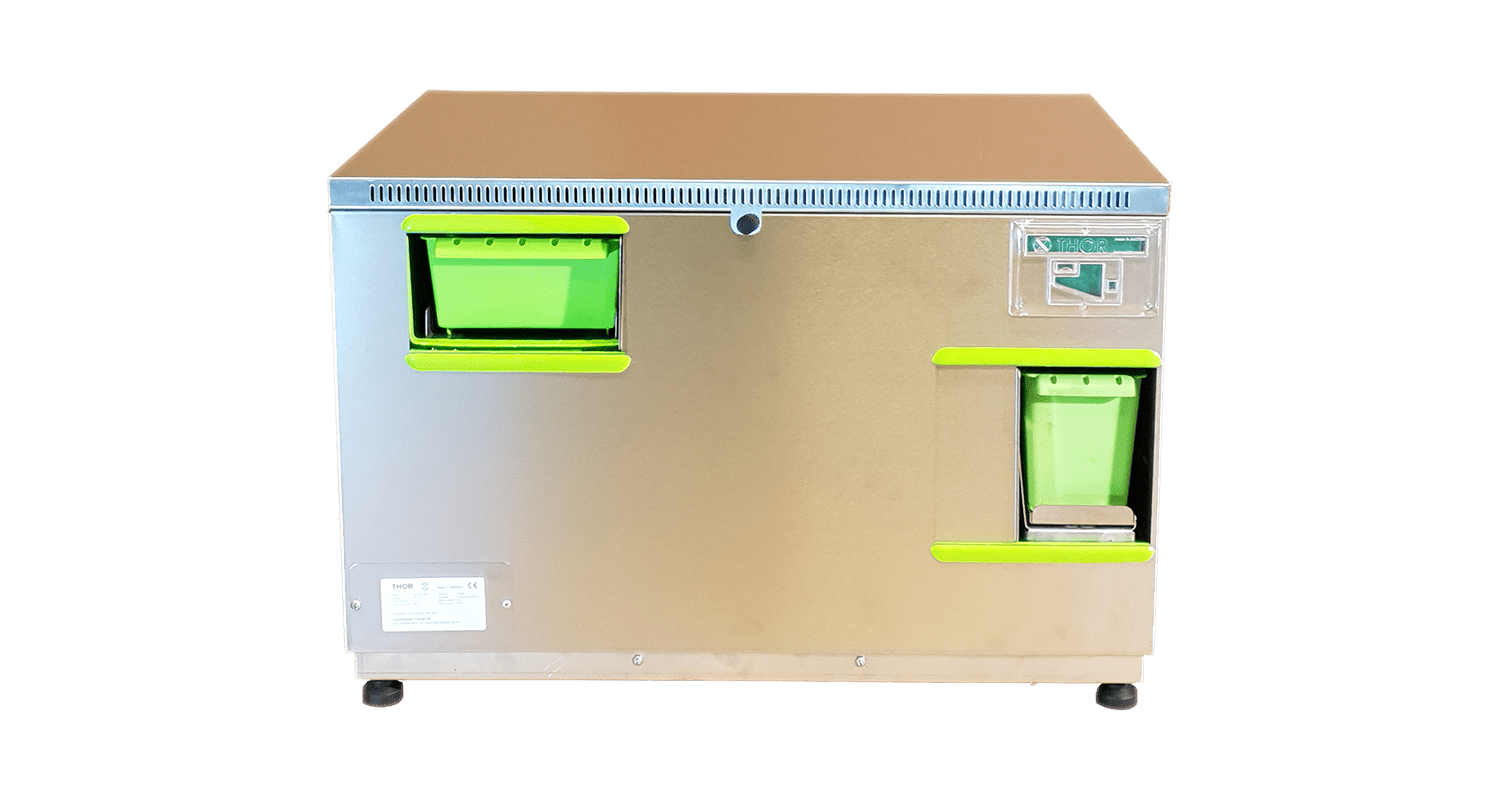

THOR automatically separates fats, oils and grease (FOG) and solids from the wastewater.

THOR is the easiest maintained grease trap for indoor use where space is scarce.

THOR is fully automatic and operates only when needed. After cleaning the water THOR goes back to standby mode and there is no need for complicated programming.

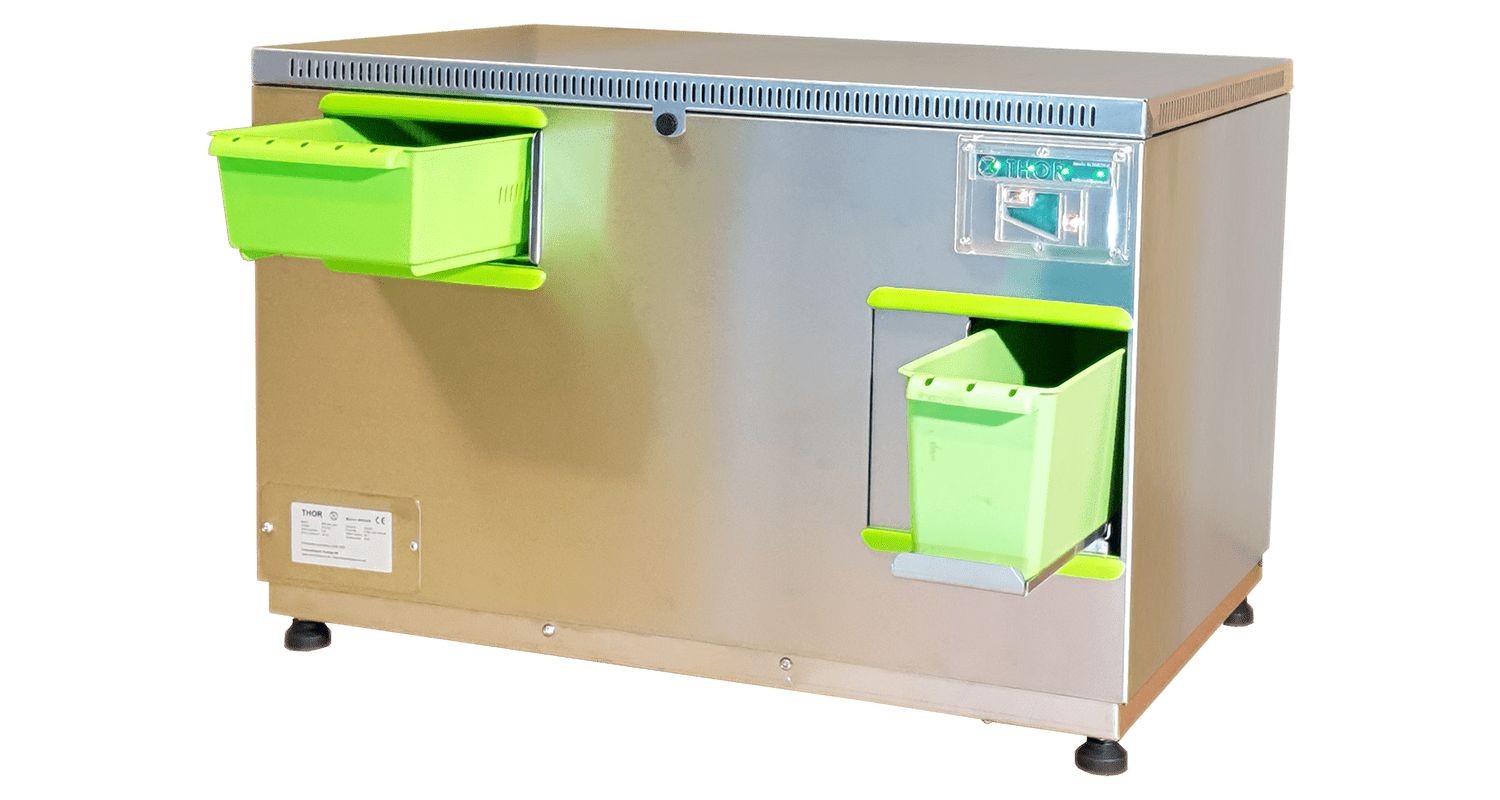

THOR will activate an alarm when the solids and the grease fat containers needs to be emptied. The unique design of the main tank combined with the pumping and filtration technology eliminates foul odours and keeps the grease trap fresh. THOR is the only grease trap on the market that automatically keeps the bottom of the main tank clean.

The environmental-friendly product development ensures a sustainable future where THOR saves the environment 5 tonnes of Co2 emissions per machine per year compared to a passive grease trap.

Fulfils the EN 1825 requirements of grease removal from water.

Accassories for THOR

Filter holder

Made in Sweden

The filter holder facilitates handling when changing filters and avoids spillage on the floor.

Made of acid-resistant sheet metal for best durability.

Disinfection system

Made in Sweden

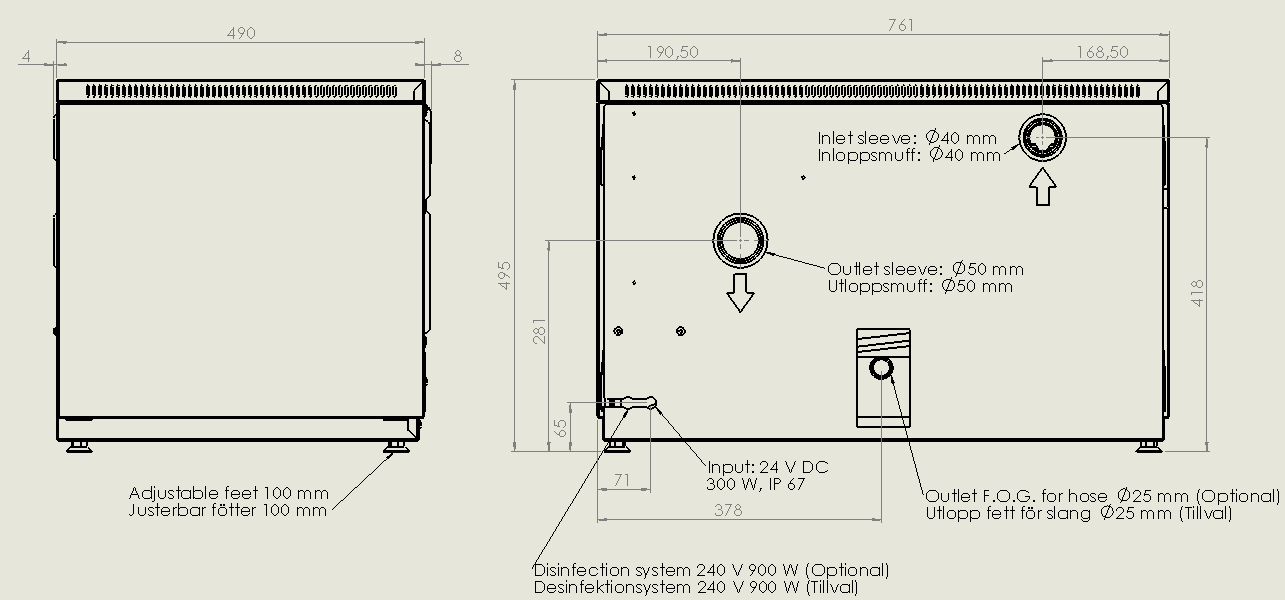

This Disinfection system for THOR heats the water up to 65 degrees Celsius causing all bacteria – that could otherwise cause foul odours – to die off, eliminating any smells.

The heat will also facilitate the separation of fats, oils and grease (FOG) as it becomes more viscous at higher temperatures.

The system is especially recommended when THOR is connected to a sink, not in conjunction with a Dishwasher.

The system facilitates and makes less need for the maintenance and cleaning of the main tank.

Energy usage: 230V 900W

Automatic drainage

Made in Sweden

This automatic drainage system neglects the need for emptying THOR manualy. The grease gets pumped to a tank through a tube with a diameter of 25mm that conects to the back of THOR. The grase is then transported to the tank with a maximum pumpinghight of 2m.

The tube can be installed to an existing THOR or as a complement on order.

Environment & Information

Since 2014, any commercial kitchen and dishwashing facilities are required to use some sort of grease trap device to prevent grease oils and fats from reaching the public sewage.

Examples of such businesses can be Hotels, Theatres, Restaurants, Schools and Colleges, Cafes, Pubs and Inns, Conference Centres, Take-Aways, Food Manufacturers, Bakeries, Golf Courses, Canteens at factories and Offices, etc.

Check with the water authorities with your local municipality for rules and regulations.

THOR can be fitted and applied to every Dishwasher, kitchen and suage piping. And is quick and easy to install

Every kitchen for commersial use is requiered to have a grease trap installd in order to properly sepereate grease and water

Units and parts are shipped in conjunction with orders in order to preserve the environment and not to create rest products

All cartons, plastic, and containers that come with the individual pieces for THOR before the assembly gets recycled or reused in order to preserve the environment

Pasive & aktive grease traps – the difference

A passive grease trap is normally situated underground, inside or outside the premises.

It is the oldest form of construction and is basically a big tank where the water is slowed down to let Fats, oils and grease (FOG) gradually rise to the surface and sediment and solids sink to the bottom. It is a slow procedure causing significant methane and hydrogen sulphide gases to be formed over time and dispensed into the open air through ventilation.

A passive grease trap needs to be pumped out once a month, at a cost, to get rid of the FOG, sediments and solids. It is then transported to a sewage treatment plant to be recycled as fertilisers or biogas.

THOR – an active grease trap – requires little space and can easily be placed directly at the source.

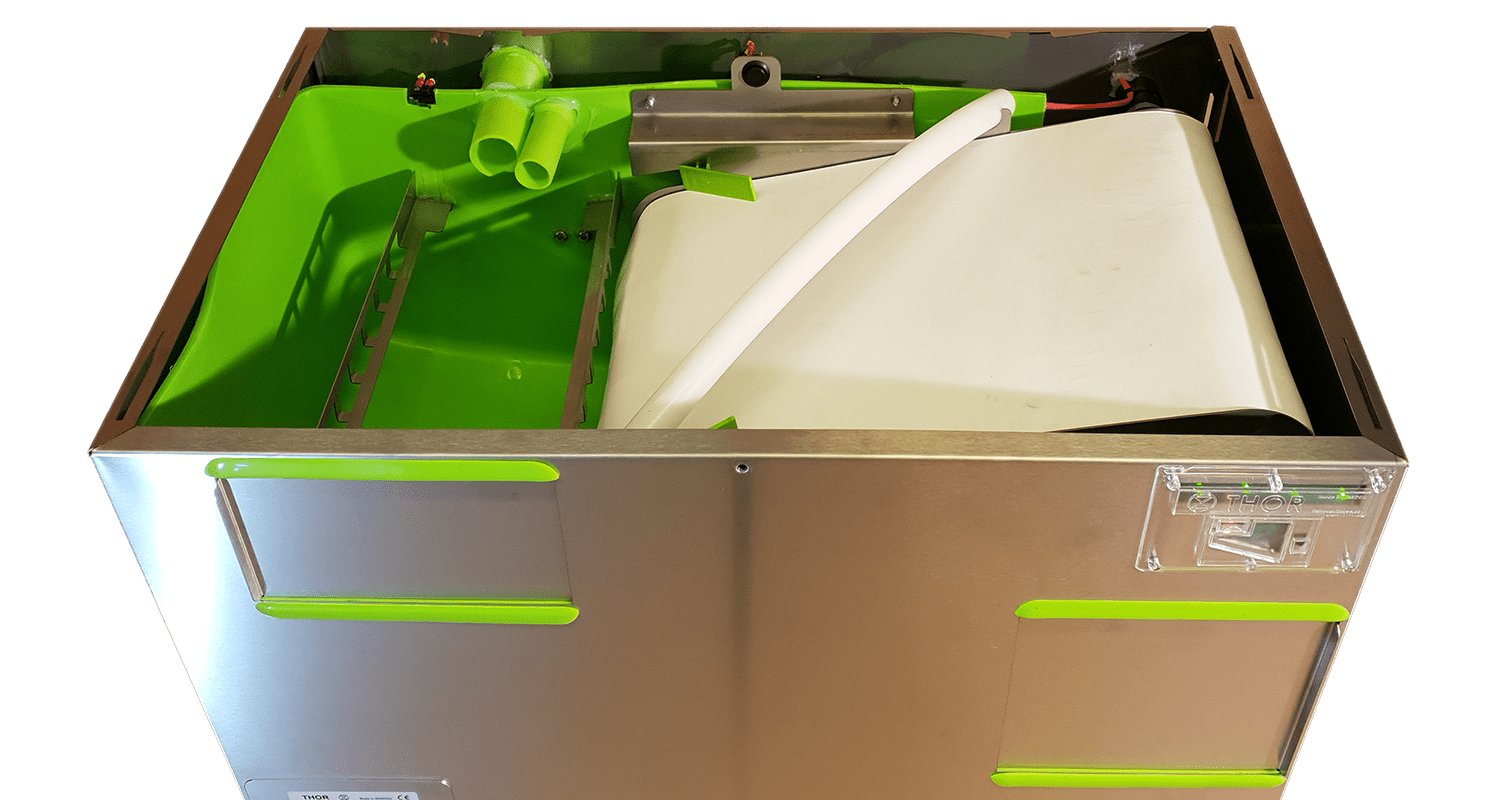

The effluent first passes through a filter removing solids, the water then reaches a tank where the water is slowed down. The FOG floats up to the surface where it is directly removed with a transportation belt to be collected in the FOG container.

THOR’s unique design of the tank’s bottom lets the sediment be pumped up to the filter again until it is totally eliminated. This process prevents methane and hydrogen sulphide gases from forming.

THOR saves the environment up to 5 tonnes in Co2 emissions a year compared to a passive grease trap.

The FOGs can then be recycled as biodiesel and the solids as biogas and fertilisers.

Joakim Fiedler – the developer of THOR – has over 25 years’ of environmental-friendly product development experience, which has resulted in rigorously optimised functionality in all and every design and product that he has developed. The materials themselves are sourced to have as little impact as possible on the environment in the manufacturing and recycling process – smart and simple solutions for optimal longevity.

The grease trap THOR effectively cleans the wastewater at the source. THOR is the only grease trap on the market that automatically cleans the bottom of the tank to eliminate odours, this results in a prevention of formation of methane and hydrogen sulphate gases – a problem associated with similar constructions on the market. THOR – in part thanks to above-mentioned technologies -saves the environment up to 5 tonnes of hydrogen sulphate emission a year.

The collected solids and fats, oils and grease can be recycled to biogas and biodiesel.

Retailers & References

Become a Retailer!

If you want to become a retailer for the grease trap THOR then feel free to contact us in the constact area at the bottom of the page. You can click on this link to get to the right place.

References

Contact us

FETTAVSKILJAREN HEAD OFFICE SWEDEN

Fettavskiljaren Sverige AB,

Flaggskär Gullberna Park,

371 54 KARLSKRONA, SWEDEN

Tel: 0470-48800

E-post: info@fettavskiljaren.se

FETTAVSKILJAREN HEAD OFFICE ENGLAND

Fettavskiljaren Sverige AB,

31 Rathdallan, Well Road Warrenpoint

Tel: +44 (0)28 4175415

Mob: +44 (0)787 65 62 410

E-mail: sales@fettavskiljaren.co.uk